TETRAS ®

|

TETRAS ®

TETRAS, NEW LEADING TECHNOLOGY OF TETRAS AXIS CONSTRUCTION IMPROVES THE TEAR STRENGTH AND DIMENSIONAL STABILITY OF FABRIC IN ALL DEIRECTIONS. MAIDAI CO,LTD. DEVELOPED THE SENSATIONAL WORLD'S FIRST MASS-PRODUCTION MULTI(TETRA)-AXIAL LOOM IN 2000. TETRAS, IT'S HIGH QUALITY AND FLEXIBILITY HAS UNLIMITED POTENTIAL IN PROGRESSING HIGHLY-TECHNOLOGICAL SOCIETY.

TETRAS CHARACTERISTICS

BREAK IN MULTI PHASE |

HIGH TEAR RESISTANCE |

DIMENTIONAL STABILITY |

HIGH ABSORPTION AND DISPERSION OF STRESS |

POSSIBILITIES FOR ANY APPLICATION WITH ANY MATERIAL |

POSSIBILITIES FOR ANY APPLICATION WITH ANY MATERIAL

UNLIMITED POSSIBILITIES OF TETRAS FEATURED BY THE COMPARISON WITH BI-AXIAL WOVEN FABRICS

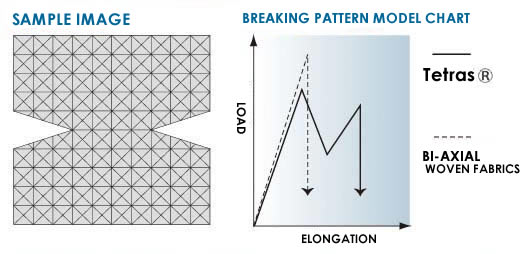

BREAKING PATTERN MODEL

|

TETRAS IS ABLE TO KEEP IT'S PATTERN UNDER EXTRAORDINARILY HIGH DESTRUCTIVE STRAIN CONDITION AND BREAK IN MULTI PHASE THOUGH BI-AXIAL WOVEN FABRIC IS BROKEN EASILY. IT SHOWS THE HIGH IMPACT RESISTANCE AND SAFENESS OF TETRAS. |

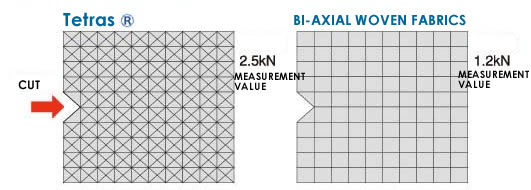

TEAR RESISTANCE

●COMPOSITION OF TETRAS FABRIC/NYLON MULTI-FILAMENT1400DTEX WEIGHT PER UNIT AREA 286g/㎡ ●EXAMINATION METHODLT APPLIES CORRESPONDINGLY TO THE JIS L 1096 C LAW (TORAPEZOID METHOD). |

|

|

TEAR RESISTANCE OF TETRAS IS OVER TWICE AS STRONG AS BI-AXIAL WOVEN FABRIC AND IT MINIMIZE THE EXTENSION OF DAMAGE. |

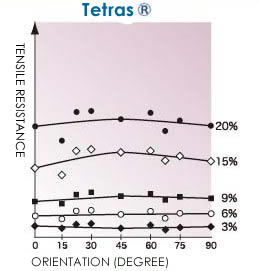

DIMENTIONAL STABILITY

|

|

| TETRAS IS STABLE AGAINST FORCE FROM ANY DIRECTION. | BI-AXIAL FABRIC IS UNSTABLE WITH DIAGONAL FORCE. |

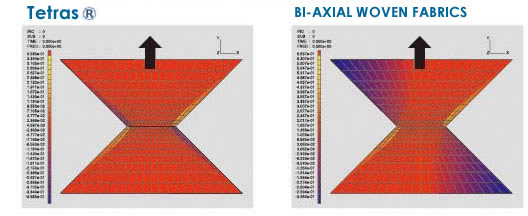

STRESS ANALYSIS OF LAMINATED FABRIC

|

BI-AXIAL WOVEN FABRIC SHOWS MINUS SHEAR STRESS IN DIAGONAL DIRECTION AND PLUS IN OTHER DIRECTION. LARGE GAP OF STRESS CAUSES THE DEFORMATION, FLAKING, CURVE, WRINKLE AND BREAK. SHEAR STRESS OF TETRAS IS STABLE IN ALL DEIRECTION AND FABRIC IS DIMENTIONALLY STABLE. |

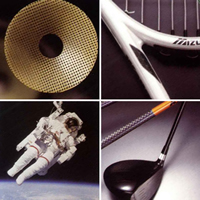

TETRAS PRODUCTS AT PRESENT AND IN THE FUTURE

|

|

| TETRAS ENABLES COMBINATION OF MANY MATERIALS AND IT IS ADOPTED IN VARIETY OF INDUSTRIAL APPLICATIONS SUCH AS TENNIS RACKETS, SHAFTS OF GOLF CLUB AND OTHER SPORTS FIELD AT PRESENT. IN THE FUTURE, WE EXPECT TO DEVELOP NEW MARKET PLACE,SUCH AS, AREOSPACE, VEHICLE, APPAREL, MEDICAL, WELFARE, CONSTRUCTION AND FURNITURE. TETRAS IS A DREAM FABRIC. |  |